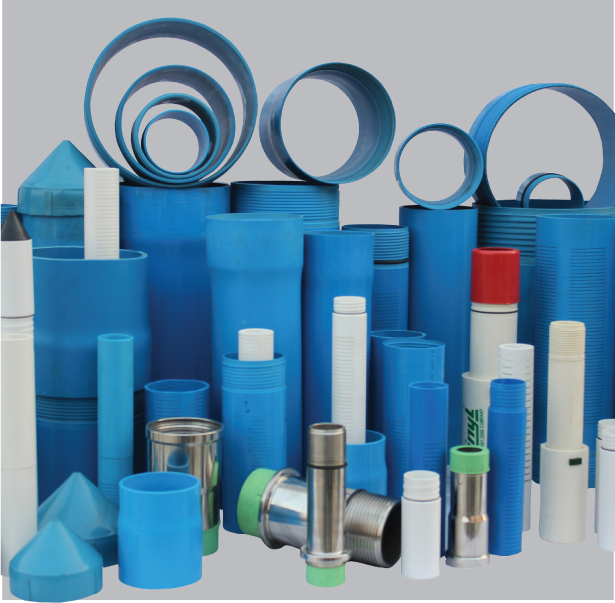

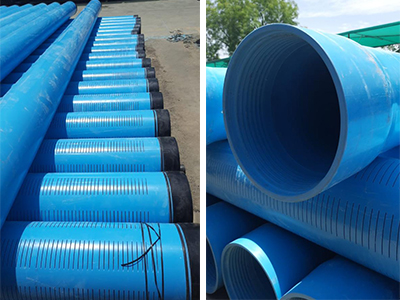

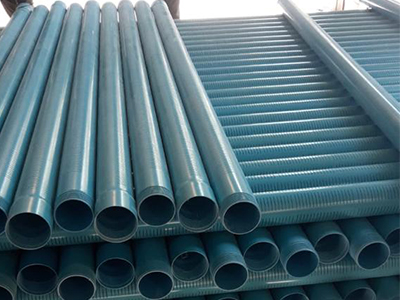

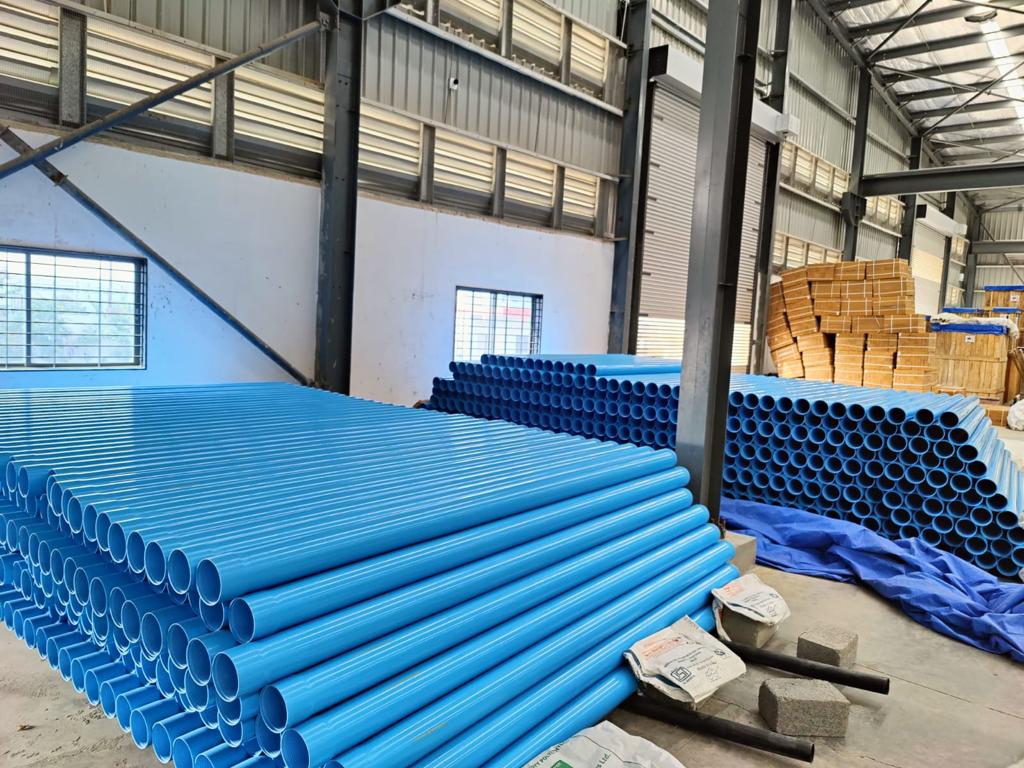

UPVC CASING & SCREENS

Best uPVC Well Casing and Screen Pipes for Building Water Wells For applications involving bore holes and bore wells, casing pipes and screen pipes are employed. It stops the earth from encircling the bore well, and the screen allows water to seep into the well so that it can be pumped. As uPVC Casing & Screen Pipes are denser than water, they have a distinct advantage in high-quality construction. A relatively high yield stress of 55Nlimm is seen. The pipe’s exceptional rigidity is also achieved with a high enough modulus of elasticity, preventing the pipe from deforming unintentionally.

Category: Accessories

Shipping & Delivery

Related products

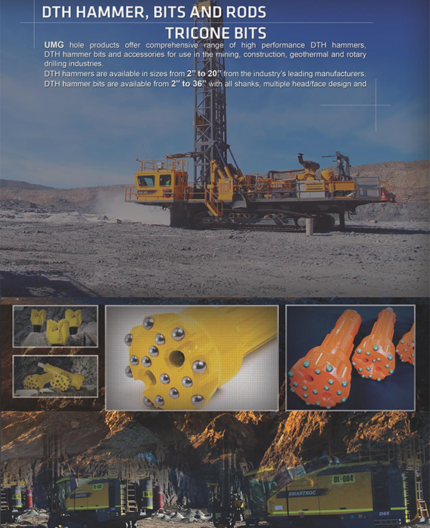

FOUNDATION DRILLING

Tricone Drill Bits

Moiz Heavy Equipment Advanced Performance (AP) tricone drill bits are supplied using aircraft quality steel and premium carbide grades developed to suit the toughest application. Computerized designs using solid modeling, computerized supplies processes using the latest in CNC equipment and computer process controlled heat treatment ensure consistent, high quality, drill bits. Moiz Heavy Equipment field staff and engineering work directly with our customers to test, report, and analyze, critical performance criteria for each drilling condition. Using this data in cooperation with feedback from the driller and Operations management, Moiz Heavy Equipment Engineering provides a level of customization unique in the industry. Moiz Heavy Equipment recognizes, as all drillers do, that all rock is not created equal.

DRILLING PIPES & ACCESSORIES

Drill pipes

We offer drill pipes with an outside diameter range of 48 to 140 mm that are friction welded. A high strength connection is created between the tube and tool joints by the regulated process of friction welding. Bigger pipes that are 140mm or larger are welded using traditional techniques. Partnering with the top European material suppliers assures the production of high-quality goods. Cold-drawn Seamless Tubes guarantee straight, highly-stable pipes without scaling. With a hard surface for wear resistance and a robust core for fatigue endurance, our tool joints are composed of micro alloy steel. The top global provider of thermal processing services conducts our heat treatment. Together with other threads offered on the market, we offer API threads. After supply, API approved thread gauges are used to examine the threads.REVERSE CIRCULATION HAMMERS

Air core drilling and reverse circulation drilling are comparable. Via an inner tube, the cuttings are brought back to the surface and collected for subsequent use. Either rotary drilling or percussive drilling using a down hole hammer is used for this kind of drilling. Drilling techniques with reverse circulation are frequently used for mineral exploration. When a solid core is not required, continuous samples can be extracted from the ground using RC.

Pumping air or water into a side inlet air swivel during RC drilling. The air is then forced down the pipe's exterior. The air is flushed and cooled as soon as it contacts the drill bit, but it also creates a hoover that forces the air and cuttings up the center of the drill string and into the inner tube. The air then returns to the drill pipe via the top drive and is sampled in a cyclone. All of the RC equipment is supplied by Moiz Heavy Equipment. The majority of other items on the market are compatible with the RC gear.

Reverse circulation drilling offers the benefit of continual, uncontaminated samples. Moreover, Moiz Heavy Equipment offers a full variety of RC tools and accessories. For more information on RC drilling, custom RC drilling tools, and custom drilling tools, feel free to get in touch with Drill Tech International.

Drilling Rigs

ODEL MTM-150( MINI TRUCK MOUNTED) DRILL RIG TECHNICAL SPECIFICATION.

MTM-150 DTHR combination Drill Rig mounted on Tata Truck 407 (4 X 4 wheel drive) with top head drive, hydraulics driven by truck engine is capable of drilling 150mtrs.

CAPACITY: The rig is capable of drilling 200mm dia hole by over burden drilling to a depth of 20 to 25 mtrs in soft/unconsolidated formation, and 150-165 mm dia hole to a depth of 150 mtrs by DTH method in hard rock and abrasive formation.

DIRECT ROTARY DRILLING: 350mm dia hole by mud rotary (Direct Rotary) method by reaming in alluvial /sandy, soft medium and collapsible formation upto 60-75 mtrs.Depth.

Note: Above drilling capacities are possible under favourable drilling conditions only.

MAST: The mast is made of heavy duty welded, construction reinforced with suitable cross members (plates) confirming to IS standard so that it is strong enough to with stand the high drilling loads.

The Mast is capable of handling 3 mtrs (10 feet) long drill pipe and 3 mtrs long casing pipe. The rig will be provided with level indicators for proper leveling. The mast is raised and lowered by means of suitable capacity hydraulic cylinders. The mast is equipped with sufficient arrangements during night drilling. The lifting of drill rods is provided hydraulically lifting arrangements.

TOP HEAD ROTARY HEAD: Hydraulically operated top drive rotary head having variable speed range of 0-100 rpm and capable of giving a torque of about 340 Kg-m

Top Hammer

During the past year, Moiz Heavy Equipment has been creating and marketing rock drilling equipment across the Middle East and Africa. Providing top-notch goods to the international market. We already supply more than 50 nations, and we are constantly adding new sales districts.

Rock tools are made of highly wear-resistant steel and our own, in-house manufactured tungsten carbide inserts. The latest cutting-edge computer technology is used by skilled engineers to create these tungsten carbide implants.

These tungsten carbide inserts are paired with the unique steel bodies created by us using this modern computer technology to offer the client unrivaled consistency in quality. Also, each bit body is identified by a supply lot number that enables accurate tracking and control throughout the whole history of the supply process for steel bodies and tungsten carbide inserts.

The mining, construction, and quarry industries have reached the highest drilling efficiency thanks in large part to the outstanding technological advancements that Moiz Heavy Equipment has been a pioneer in achieving.

HDD – Horizontal Directional Drilling

The construction method known as horizontal directional drilling (HDD) involves drilling a tunnel under a canal or other defined region and then pulling a pipeline or other utility through the tunnel.

At the entry point, the underground tunnel travels in an arc under the designated crossing area before emerging on the other side. A drill head electronically guides the drilling pipe using cutting-edge technology and highly skilled specialists to make sure the angle, depth, and exit point follow meticulously planned engineering blueprints.

(HDD) is a more recent method of installing pipes and utilities that provides higher placement accuracy and flexibility and eliminates the need for expensive digging, big teams, road closures, and other difficulties associated with conventional digging and pipe installation.

The "open cut" method, which involves digging deeper to install pipes and services, is far more disruptive than HDD and has many disadvantages. The most effective alternative for your repair, maintenance, or installation project is probably horizontal directional drilling.

SPARE PARTS FOR HYDRAULIC DRILL RIGS

We offer world class spare parts which are used by well known brands in the sector… The machineries include Crushers, Rock Drills and Drifters, Rock Breakers, Concrete Pumps and so on.

ALTERNATIVE SPARE PARTS

HYDRAULIC DRILLING RIG AND DRIFTER SPARE PARTS

- HYDRAULIC ROCK DRILL PARTS

- HYDRAULIC BREAKER PARTS

- EARTH MOVING MACHINERY PARTS